The Unsung Hero of Microgreen Success: Cleanliness

The Unsung Hero of Microgreen Success: Cleanliness

Microgreens are a delightful addition to any plate, bursting with flavor and nutrients. But behind those tiny, vibrant greens lies a crucial, often overlooked aspect of successful cultivation: rigorous cleaning and sanitization of trays and equipment. Whether you're a seasoned grower or just starting your microgreen journey, maintaining a sterile environment is paramount for healthy harvests and preventing the spread of disease.

Why is Cleaning and Sanitizing So Important?

Imagine a petri dish – that's essentially what a seed starting tray can become if left uncleaned. Microgreens, grown in close proximity and in warm, humid conditions, are susceptible to a range of fungal and bacterial diseases. These pathogens thrive on organic matter left behind after a harvest, creating a breeding ground for problems that can devastate your next crop.

Here's a breakdown of the key benefits of meticulous cleaning and sanitizing:

Disease Prevention

Damping-off, a fungal disease that attacks seedlings, is a common culprit of microgreen failure. Cleaning eliminates fungal spores and other pathogens that cause this and other diseases.

Bacterial infections can also spread rapidly in a contaminated environment, leading to wilting, discoloration, and ultimately, crop loss.

Reduced Mold Growth: Mold thrives in moist environments and on decaying organic matter. Cleaning removes these food sources, significantly reducing the risk of mold growth.

Improved Seed Germination: Clean trays provide a sterile environment for seeds to germinate, promoting healthy and consistent growth.

Enhanced Crop Yields: By preventing disease and promoting healthy growth, cleaning and sanitizing contribute to higher yields and a more consistent harvest.

Food Safety: If you are selling your microgreens, or even growing them for your own consumption, food safety is paramount. Cleaning and sanitizing reduces the risk of foodborne illnesses.

The Cleaning and Sanitizing Process

A thorough cleaning and sanitizing routine involves two distinct steps, cleaning and sanitising.

Cleaning

- Begin by removing all residual soil, plant matter, and debris from the trays and equipment.

- Wash the trays with hot, soapy water, using a scrub brush to remove any stubborn residue.

- Rinse thoroughly with clean water.

Sanitising

Once cleaned, the trays must be sanitised to kill any remaining pathogens. Several sanitising solutions can be used:

- Bleach Solution: A diluted bleach solution (1 part bleach to 10 parts water) is a common and effective sanitizer. Allow the trays to soak for 10-15 minutes, then rinse thoroughly with clean water.

- Hydrogen Peroxide: A 3% hydrogen peroxide solution can also be used as a sanitizer. Spray or soak the trays, then allow them to air dry.

- Vinegar: While not as powerful as bleach or hydrogen peroxide, vinegar can be used as a natural sanitizer.

- Commercial Sanitisers: Look for horticultural sanitisers specifically designed for greenhouse and growing environments.

- Ensure all tools, such as scissors, spray bottles, and watering cans, are also thoroughly cleaned and sanitised.

- Allow all equipment to air dry completely before reusing.

Consistency is Key

Cleaning and sanitising should be performed between each use, without exception. This consistent practice is the foundation of a healthy and productive microgreen operation. By prioritising cleanliness, you'll create an optimal growing environment, minimize the risk of disease, and enjoy a bountiful harvest of delicious, nutritious microgreens.

UV Light Sanitisation

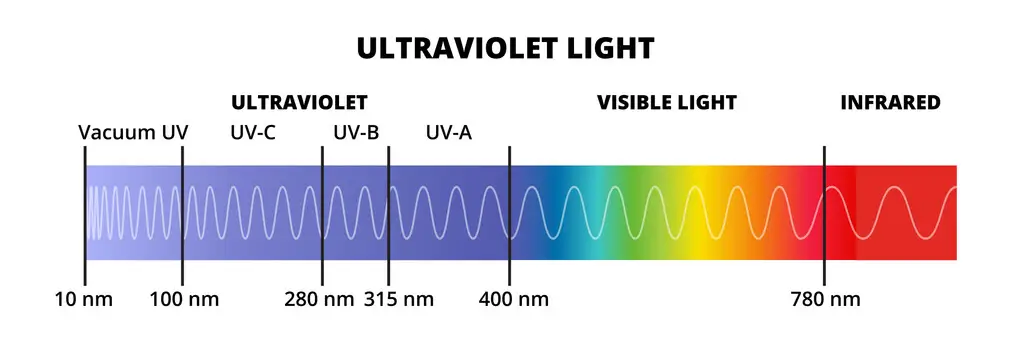

UV light has sanitising properties, and sunlight is a source of UV radiation. Here's a breakdown of how UV light and sunlight relate to sanitizing microgreen trays.

Effectiveness: UV-C light, in particular, is very effective at killing bacteria, viruses, and fungi by damaging their DNA. Dedicated UV sanitizing equipment can be very useful.

Considerations: UV light's effectiveness depends on the intensity and duration of exposure. It only sanitizes surfaces directly exposed to the light. Safety precautions are essential when using UV-C light, as it can be harmful to skin and eyes.

UVC via Sunlight for Sanitisation

Potential Benefits: Sunlight contains UV radiation, which can contribute to sanitising surfaces. Allowing trays to dry in direct sunlight can help to reduce the presence of pathogens. The drying effect of the sun also helps to inhibit mold growth.

Limitations: The intensity of UV radiation from the sun varies depending on the time of day, weather conditions, and location. Sunlight may not provide consistent or complete sanitisation compared to dedicated UV equipment or chemical sanitisers. It is hard to control the level of sanitisation that the sun provides.

Practical Application

Using sunlight as a supplementary sanitising method can be beneficial. After washing and cleaning the trays, placing them in direct sunlight to dry can add an extra layer of protection. It is most effective when used in conjunction with other cleaning methods.

While sunlight provides some sanitising effects, it's generally recommended to use it as a supplement to other cleaning and sanitising methods. For reliable and consistent sanitisation, especially in commercial settings, using proven sanitising solutions (like diluted bleach or hydrogen peroxide) is crucial. When using sun light, it is most effective when the trays have been cleaned of all debris first.

Therefore, while the sun can help, it should not be relied upon as the sole method of sanitisation.

UV-C via Lamps for Sanitisation

UV lamps, particularly those emitting UV-C light, can be used to sanitise microgreen trays and equipment. However, it's crucial to understand the risks and take necessary precautions. Here's a breakdown:

Effectiveness: UV-C radiation is highly effective at killing microorganisms, including bacteria, viruses, and fungi, by damaging their DNA. This makes it a potent tool for sanitizing surfaces.

Applications: UV-C lamps can be used to sanitize trays, tools, and even growing areas. They offer a chemical-free sanitizing option.

Precautions

Eye and Skin Protection: UV-C radiation is extremely harmful to eyes and skin. Direct exposure can cause severe burns and long-term damage. Never look directly at a UV-C lamp, and ensure that skin is fully protected during operation. Wear appropriate protective equipment, such as UV-blocking safety glasses and clothing.

Proper Usage: Follow the manufacturer's instructions for operating UV-C lamps. Ensure that the lamps are used in a controlled environment where accidental exposure is minimized. Use timers or automated systems to control exposure time and prevent overexposure.

Indirect Exposure: Even indirect exposure to reflected UV-C light can be harmful. Ensure that the surrounding area is shielded or that the lamps are used in enclosed spaces.

Material Degradation: Prolonged exposure to UV-C radiation can degrade certain materials, such as plastics. Consider the materials of your trays and equipment when using UV-C lamps.

Ventilation: While UV-C does not produce fumes in the way that chemical sanitizers do, it is always wise to ensure proper ventilation of any enclosed space where UV-C lights are used.

Reliability: Ensure that the UV-C lamp is of good quality and that it is emitting the correct wavelength of UV-C light. Low quality lamps may not be effective.

Key Considerations

While UV-C lamps can be effective, they only sanitize surfaces directly exposed to the light. Thorough cleaning to remove debris is still essential before using UV-C sanitisation. When deciding to use UV-C lamps, it is very important to prioritize safety. By taking these precautions, you can safely and effectively use UV-C lamps to enhance your microgreen sanitisation practices.